Production with quality

The series production of e.g. deep-drawn parts is subject to constant quality control in accordance with DIN EN ISO 9001:2015. It is our goal to detect and eliminate errors before they arise. Every employee therefore bases their daily work on a zero-defect strategy.

As a long-standing partner of the automotive industry, our standard is based on ISO / TS 16949. For us, product and material traceability are therefore a matter of course.

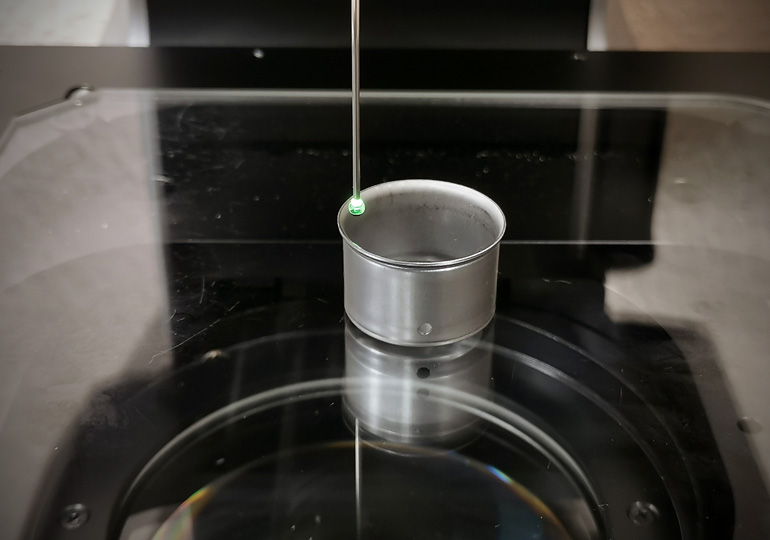

In order to safeguard the processes, product-specific test plans are developed together with the customer. The associated statistical process control is therefore a fundamental building block for meeting the high quality requirements of our customers.